Project Description

Produkte > Visuelle Überwachung > Liquid Level Gauges

Liquid Level Gauges

Ranger liquid level gauges were built according to a modular system and thus combine a wide variety of options and cost efficiency. They meet the highest requirements when it comes to corrosion resistance and stability, since the base material used is stainless steel (316L).

Ranger liquid level gauges made of stainless steel 316L (1.4404)

INOX equipment is synonymous for high resistance against acids and caustics, seawater proof and widely accepted in a large range of industrial applications, in medical use as well as food industry, chemical and petro industry (on and off shore), mining, water treatment (desalination !), nuclear technology etc.

Colored materials i.e. Al, Zn, Sn, Cu and their alloys don’t have these characteristics.

INOX devices are designed for highest demand in function and safety. They can be protected according to the ATEX directives.

The ordering number is the combination of the listed modular system. e.g. Type LAGS2R150-V-F is a Stainless Steel indicator with a vertical connection thread (Style A), glass indicator pipe, a standard vented cap, a 1/4″ BSPT adaptor thread, 150 mm nominal size, FKM and Aramid fiber gaskets.

A = Vertical

R = Horizontal rotatable (adjustable)

F = Horizontal, Banjo Bolt with Port

G = Glass (Borsilicate)

P = Acrylic Glass (PMMA)

X = ATEX-Version Glass + Steel Cover + Protection pipe PMMA

S = Standard (vented)

C = Closed system (G1/8)

R = Refill Cap

- Deckelparade Detail

- Deckel geschlossen

0 = Banjo Bolt only (G1/4″)

1 = 1/8″

2 = 1/4″

3 = 3/8″

4 = 1/2″

5 = 3/4″

R = BSPT tapered (EN10226)

G = BSW parallel (DIN 259)

N = NPT (US-Norm ANSI)

Available nominal sizes: 80, 100, 125, 150, 175, 200, 250, 300

For installation dimensions see dimensions table for form A or R.

V = FKM (e.g. Viton® )

N = NBR

F = Aramid fiber

T = Glass fiber reinforced PTFE

- Connection options

- Level marks

INOX Varia liquid level gauge

The visible range is from 40 up to 2000 mm. The advantage of this version is that the length of the transparent pipe can be adapted to practically any hole distance. The transparent plastic tube also provides 3D visibility.

Material: Stainless steel (1.4404/316L), tube acrylic glass

- Dimension drawing

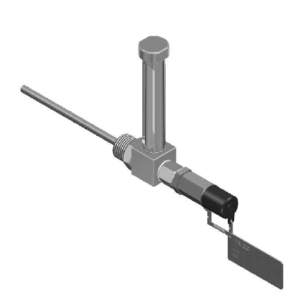

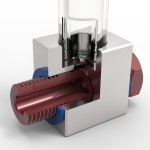

Vista 3D Liquid level gauge

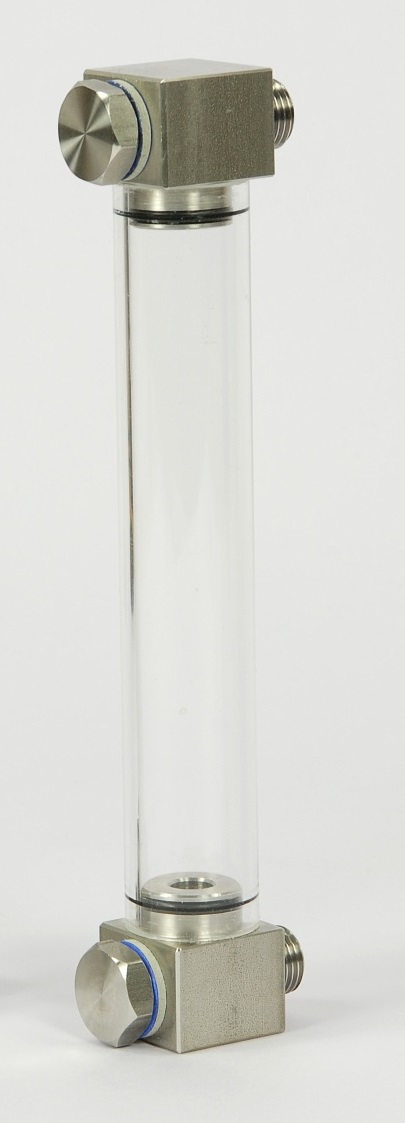

Vista is our new innovative liquid level gauge characterized by a solid design, offering all-round visibility through the plastic tube which is firmly fixed on the metal body. The length of the plastic tube may vary and level marks can be made according to your order. Available with a cap suitable for closed system applications or a refill cap.

In comparison with the standard liquid level indicators made of brass, Vista offers significant advantages. Foreign particles or water from the environment can not enter the system, which is often the case with standard brass indicators because of their fully exposed ventilation hole. Vista indicators are vented through a unique labyrinth (IP55).

- Horizontal with banjo bolt

- Section view

- Horizontal with lock nut

- Standard indicator and Vista comparison

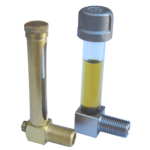

Brass oil level gauges

These units are used in industry to visually check the fluid level within a reservoir or gearbox. Vertical and angled oil level gauges are available in brass.

a) Horizontal with locknut (DIN 3018 form B + C)

b) Horizontal with banjo coupling (DIN 3018 form D + E)

c) Vertical (DIN 3018 form A)

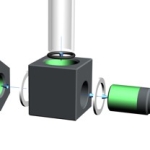

Banjo bolt for liquid level gauges

The main body of the INOX liquid level gauges is mounted to your equipment with a banjo bolt, which is available in 2 versions. The banjo bolt with a simple hole is used to connect the indicator to the fluid system whose level is to be observed. The opposite side is closed. Additionally a banjo bolt with a through bore is available, which was designed in order to provide easy access to your system, enabling sensor technology to be installed, e.g. low level detection with our optical sensor.

Through the additional port the cleanliness of the oil can also be measured simply by installing a sampling port. Another available option is to install a thermometer.